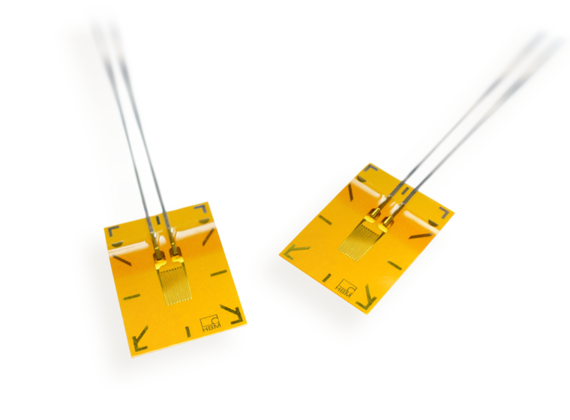

Strain Gages & Load Cells

Strain gages and load cells serve to measure forces from pulling, pushing, twisting, and weights of all sizes.

They work by stretching thin foil designed in a zig-zag pattern. The gage must be bonded (glued) to the part you wish to measure. When the foil is elongated, electrons move less freely, increasing the electrical resistance. Since there is a change in resistance (R), there is also a change in the voltage (V) across the gage.

History

Georg Ohm discovered the relationship between voltage, current and resistance using the equation V = IR. Units of electrical resistance are named after him.

1827

Charles Wheatstone put (4) individual resistors in a cool diamond shape to make the Wheatstone Bridge configuration.

1868

Wheatstone Bridge

As voltage is sent through the bridge, small changes in voltage from stretching can be measured with reduced interference from other variables such as temperature.

For example, the change in voltage between diagonal points D and B can be measured as one goes up and the other goes down. The voltage between two points is known as a differential measurement. These outputs are tiny voltages in the millivolt range (1/1000 V).

Turn It Up

Since they are so small, the tiny voltages can be amplified in order to make them easier to measure. Common amplifications, called gains, range between 100x and 1200x.

Ship It Off

Next, this amplified signal can be read as an analog voltage or fed to an analog-to-digital converter (ADC). Once in a digital format, it can go to a meter display, out on a CAN (Controller Area Network) Bus, or sent as a wireless radio signal.

Example of a rugged strain gage amplifier/conditioner

module with CAN Bus Output. (Techmor Inc)

Quick Tips

Select the best gage/load cell for the material and stress level to get the biggest response

Contact the gage manufacturer for help with your application

Keep the gage connection wires short to reduce noise

Electrical fields are all around us and low-voltage wires can act like antennae to pick up noise.

Set your gain value so the maximum strain will give the maximum readable output

This will use the full range of your instrumentation, and give the best resolution.

Shielding

If you use a shielded wire from the strain-gage to your amplifier, only ground the wire at the amplifier end. Do not tie it to ground at the strain-gage end.

Conclusion

Strain gages and load cells can accurately measure loads, strain/stress, and torque with some knowledge and proper selection.

See techmor.com for strain gage amplifiers, CAN bus tools, and wireless solutions.

https://www.hbm.com/en/0014/strain-gauges/

http://www.vishaypg.com/micro-measurements/stress-analysis-strain-gages/

http://www.kyowa-ei.com/eng/product/category/strain_gages/index.html

11148 Treynorth Drive

Suite A

Cornelius, NC 28031

(704) 769-0001

Maximize Your Metrics with Techmor's Measurement Toolsre

Contact Us

Precision metrics measurement is a critical aspect of many industries, particularly in the automotive sector where accuracy and consistency are essential to ensure quality and safety. From engine performance to vehicle emissions, precise measurements are crucial for meeting regulatory requirements, improving efficiency, and enhancing the overall driving experience.

One of the most significant challenges in precision metrics measurement is achieving the level of accuracy required for reliable results. This requires careful calibration of measurement instruments, as well as attention to environmental factors such as temperature and humidity that can affect the accuracy of measurements. In addition, data analysis and interpretation play a critical role in determining the relevance and usefulness of measurement data.

Automotive applications of precision metrics measurement include everything from engine testing to fuel efficiency analysis, emissions testing, and more. Advances in technology have enabled more precise and efficient measurement techniques, such as the use of laser-based sensors and automated testing systems that can perform measurements quickly and accurately.

One of the most promising areas of development in precision metrics measurement for automotive applications is the use of artificial intelligence (AI) and machine learning (ML) to automate data analysis and interpretation. By using algorithms to analyze large amounts of measurement data, AI and ML can provide valuable insights into vehicle performance, identify areas for improvement, and help automotive manufacturers develop more efficient and reliable products.

Overall, precision metrics measurement and its applications in the automotive industry are critical for ensuring quality, safety, and efficiency. Advances in technology and the use of AI and ML are likely to play an increasingly important role in the future of precision measurement and automotive development.

Copyright 2024 Techmor Inc.